Applications of sacrificial anode systems

The method of sacrificial anodes and its applications

In the sacrificial anode method, the current required to combat the corrosion of the structure is provided by another metal, which is usually made of zinc, aluminum and magnesium. Because these sacrificial anodes do not have the ability to provide high current, sacrificial anodes are used where low current is required to protect against corrosion.

Applications of sacrificial anodes include the following:

- Where the protected structure is small.

- Items that do not have access to electricity, such as offshore platforms or pipelines.

- Items where the use of electricity is dangerous, such as inside oil storage tanks.

- Where soil specificity is low. The use of sacrificial anodes in high-strength soils is not recommended due to reduced output current.

- To fix the wandering currents.

According to the above, you can get the necessary information about cathodic protection from the sales and development unit of Tavanazob Sana’ati Kavir Company regarding the applications of the sacrificial anode system, and follow other questions about the applications of the sacrificial anode system from the sales support department.

In this regard, you can receive the contact numbers of the sales and development unit from the relevant department or send questions related to cathodic protection or sacrificial anodes via e-mail.

- Published in Articles, Educational, Scientific

Cathodic protection of aboveground storage tanks

Protection of aboveground storage tanks against corrosion

Both sacrificial anodes and impressed current system are used for cathodic protection of aboveground storage tanks. In this method, the protection of the inner surface of the tank is done by the method of sacrificial anodes and the protection of the outer surface of the tank floor is done by ribbon MMO anodes. Because the tank has large dimensions and therefore high weight, to support the weight of the tank, ribbon anodes with a flat cross section are used. Also, flat anode will lead to better flow in the tank floor. Before placing the bottom and body of the tank in the desired location, first the anodes are installed in the correct way, then a special layer of sand is poured on it and finally the bottom of the tank is placed on the sand.

Cathodic protection of the tank floor

The impressed current cathodic protection system is placed in the bottom of the tank in such a way that first the ribbon MMO anodes are laid in the form of horizontal strips in the bottom of the tank and in order to connect the anodes to the rectifier, the conductor bar which are titanium strips without cover, are used perpendicular to ribbon anodes. The connection of titanium bar to ribbon anodes is done by spot welding. The negative phase of the rectifier is connected to several points of the tank body. The positive phase of the rectifier is connected to a junction box and then through it, titanium bars is attached to the anode. The job of titanium is to deliver current to the anode. These connections are well done in different places so that no interruptions occur. Also, a number of permanent reference electrodes are placed on the bottom of the tank so that the potential of different parts of the tank can be measured.

![]()

In the past, other methods were used to cathodically protect the tank around it, such as drilling wells and placing anodes around the tank. But these methods did not bring the flow evenly to the bottom of the tank.

Cathodic protection inside the tank

The ribbon anodes inside the soil only protect the outer surface of the tank floor from corrosion. Because there is a different electrolyte inside the tank, such as water or crude oil, other anodes must be used to protect the inside of the tank. Sacrificial anodes, and in some cases impressed current anodes, are commonly used to protect the inner surface of the tank. Inside the crude oil tanks, only the sacrificial zinc anode is used.

- Published in Articles, Educational, Scientific

Types of backfill in cathodic protection system

Types of backfill

The type of backfill used in the cathodic protection system in ground substrates depends on the type of cathodic protection system used. Due to the fact that the cathodic protection system exists in two types of sacrificial anode systems and impressed current anode systems, so two types of backfill materials are also used.

Sacrificial anode systems

The sacrificial zinc and magnesium anodes used to cathodic protection of structures buried in the soil are sometimes packed in a linen bag with a backing material. These materials reduce the local corrosion of the anode by preventing the anode from coming into direct contact with the soil. It also prevents the anode from becoming passive by reacting with salts in the soil. The backfill used improves the performance of the anode by creating a low-resistance environment around the anode. These materials are generally a combination of three types of gypsum gypsum, bentonite and sodium sulfate, and the percentage of their compounds depends on the environment used.

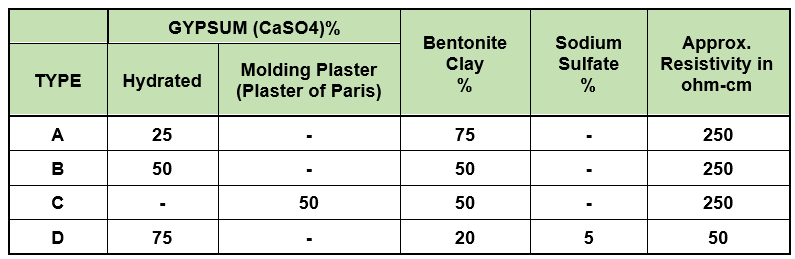

The following table shows the types of backfills according to the IPS-M-TP 750 standard:

Impressed current system

Impressed current anodes for cathodic protection of underground structures are usually surrounded by a carbon backfill. The purpose of using this support is:

- By reducing the resistance of the environment around the anode, it leads to an increase in the amount of current produced by the anode.

- As the anode level increases, the amount of current increases.

- Reduce anode consumption rate and thus increase anode lifetime.

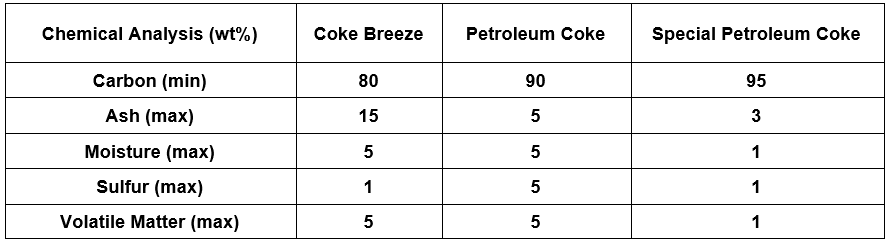

Carbon backfill according to IPS-M-TP 750 standard is available in three types of 80% metallurgical coke, 90% petroleum coke and 95% special petroleum coke.

The chemical composition of these three types of backfill is specified in the table below:

Coal coke is generally used in shallow horizontal substrates. Petroleum coke or special petroleum is used for deep wells.

- Published in Articles, Educational, Scientific

Mixed metal oxide anode (MMO) and its applications

What is a mixed metal oxide anode?

Mixed metal oxide anodes are made of a titanium substrate coated with mixed metal oxides. The coating is applied by several thermal processes on the titanium base to create a chemical resistant layer. Due to the inherent stability of titanium, this coating achieves the best performance of the anode by strengthening the conductivity of the anode.

MMO anodes have advantages such as very low consumption rate and high current capacity. Low anode consumption rate causes the anode dimensions to remain almost constant over the life of the anode. Therefore, these anodes are widely used in impressed current systems for land and marine structures.

MMO anode applications

MMO anode is used in cathodic protection system in different types of tubes, ribbons, meshes, wires and plates. These anodes can be used effectively in all environments such as soil, fresh water and saline water. Depending on the environment in which the anode is located, two types of coatings are considered for the anode. Iridium-tantalum coating is used in soil and fresh water and iridium-tantalium-ruthenium coating is used in saline water. The anode current capacity in soil, coke or fresh water is 100Amps \ m2 and in saline water is 600Amps \ m2.

various type of MMO anodes

Types of MMO anodes

- Tubular Anode

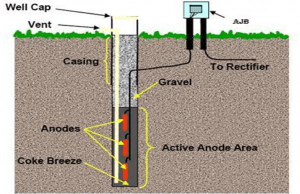

Tubular anode is the most common type of MMO anode used in cathodic protection systems. The titanium of this anode is manufactured according to ASTM B338 Grade1 standard. Tubular anodes are usually used as strings in deep wells.

cathodic protection of deep wells by tubular mmo anodes

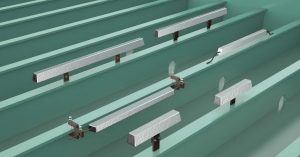

- Ribbon Anode

The titanium base of these anodes is manufactured according to ASTM B265 Grade1 standard and uses iridium / tantalum mixed metal oxide coating. This type of anode is used to protect the external bases of aboveground storage tanks. Ribbon anodes are suitable for connection to titanium conductors by spot welding to create a network under the tank that also provides a uniform distribution of current.

- Mesh Anode

Mesh MMO anodes are used in cathodic protection systems of reinforced concrete structures. Titanium mesh anode base like ribbon anode is produced according to ASTM B265 Grade1 standard and the anode quality is checked according to NACE TM0294 standard.

- Wire Anode

Titanium wire anode is an ideal cathodic protection product for protecting the bottom of tanks, submarines and pipelines. This type of anode is made of high grade titanium with a mixed metal oxide coating and has a lifetime of more than 50 years.

- Plate Anode

These types of anodes are designed as rectangular or circular plates for use on ships and vessels.

- Published in Articles, Educational, Scientific

Protection of water heater against corrosion

Maintenance of water heaters using a sacrificial anode

The use of water heaters in industry as well as in homes in various dimensions and shapes is essential. Therefore, its maintenance is very important. The water heater may run loudly over time as sediment builds up inside. This deposit may be due to natural minerals in the water or substances that result from corrosion of the sacrificial anode or the tank itself.

In a water heater, the sacrificial anode is visible as a rod that slowly erodes over time. The sacrificial anode is made of magnesium, aluminum or a combination of zinc and aluminum. The water in the tank causes corrosion of the inner steel of the tank by creating an electrolytic reaction. To protect the steel, a magnesium or aluminum rod anode is placed in place. After the anode corrodes, the tank steel begins to corrode and the tank fails.

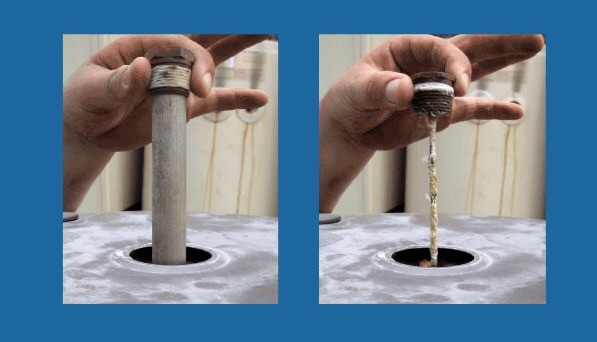

Replacement time of sacrificial tank anodes

To protect the tank steel against corrosion, the sacrificial anode of the tank should be replaced every 3 to 5 years, depending on the type of tank. The warranty period of the tank can be used to determine the time of replacement of the anodes. If the anodes are not replaced in time, the tank will continue to work, but over time, the tank steel will corrode and tank replacement will be inevitable, which will cause a lot of damage.

water heater tank corrosion

How to place the sacrificial anode in the tank

The sacrificial anodes are usually screwed to the top of the tank for easier access. Note that sometimes the length of these bars is long and you have to have enough space to take them out. Therefore, sometimes it is necessary to remove the tank to replace the sacrificial anode.

Water heater anode

What type of sacrificial anode is used in the tank?

The sacrificial anode type is usually recommended by the manufacturer. Aluminum sacrificial anode, although it may cost less, has a higher corrosion rate than magnesium anode. Also, in addition to making noise, the aluminum poured into the tank pollutes the water in the tank. Therefore, be careful never to use hot water from the tank for drinking or cooking. The most common sacrificial anode in water heater tanks is the magnesium sacrificial anode.

- Published in Articles, Educational, Scientific

Lifetime design of cathodic protection system

Necessity of designing the lifetime of the cathodic protection system

In order to protect metal structures immersed in water or buried in soil against corrosion, it is necessary to use a suitable cathodic protection system. The cathodic protection system must be designed to provide the required current for each part of the structure for the required lifetime. This requires determining the size, weight, number and type of anode. Also, the design of longevity is based on each of the cathodic protection systems, taking into account the specific conditions of those systems.

Design based on impressed current system

The calculations for impressed current cathodic protection systems are relatively simple. Since the impressed current anodes are weight stable, in this case it is only necessary to match the number of anodes with a certain output current with the amount of current required by the whole structure. The anode distribution should be such that it leads to a uniform and balanced distribution of current.

Design based on sacrificial anode system

The calculations for the sacrificial anode system are a bit more complicated. The amount of sacrificial anodes required to protect metal structures is directly related to the surface subject to corrosion. The better the initial coating, the less anodes are needed. The arrangement of the anodes on the surface of the structure is adjusted to ensure a uniform distribution of current throughout the structure.

By sacrificing its weight, the sacrificial anode provides the protection current needed. Therefore, in a sacrificial anode system, the number of anodes must not only provide the current required by the structure, but must also have sufficient weight to provide current for the designed life of the structure. The size and shape of the anode is determined by the following factors:

- Minimum and maximum output current requirements.

- Installation and connection requirements.

- Anode weight requirements required.

- To be economical.

Sacrifice anode used in the tank

Maintenance of sacrificial anodes for fixed offshore structures is generally very costly and sometimes impractical. Therefore, using the optimal number and weight for the structure under protection is very important.

In this regard, you can use the sales unit of the cathodic system and you can also buy the products of Tavanazob Sana’ati Kavir Company from the relevant postal address.

The question is, why is the design of the cathodic protection system important to us?

We will answer this question in other educational articles of Tavanazob Sana’ati Kavir Company to learn more about the cathodic protection system.

- Published in Articles, Educational, Scientific