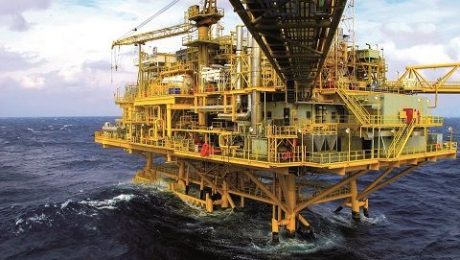

Cathodic protection of offshore structures

Offshore structures

Offshore structures include platforms, semi-submerged structures in water or wells, pipelines, and underwater equipment. Offshore steel structures are designed based on two criteria of strength coefficient and strength. Its strength coefficient depends on the amount of surface material that is lost during the corrosion process. Its strength is affected by pitting corrosion. Therefore, a proper and accurate design of a corrosion control system is essential.

The outer area of offshore fixed steel structures is divided into two categories according to its surroundings.

The part of the structure that is adjacent to the air and above the water surface and must be protected by a suitable coating. Another part that is under water and to protect it, a precise cathodic protection system is required.

Cathodic protection system

When the structure is inside the electrolyte (water), the potential difference between the different points of the structure causes a current to flow between these points. This current causes the part that has a more negative voltage to corrode. The principle of cathodic protection by creating a more negative potential around the structure leads to the potential of different parts of the structure being the same. Therefore, the steel structure is protected against corrosion. This current may be supplied by various sources such as transformer rectifiers or sacrificial anodes.

Cathodic protection by sacrificial anode

The sacrificial anode is usually a metal that has a more negative potential than the structure. The connection of the anode to the structure causes a current to flow inside the electrolyte from the anode to the structure. For offshore structures, the sacrificial anodes are made of aluminum or zinc. Aluminum sacrificial anode is used more than zinc sacrificial anode due to its “better current to weight ratio” feature.

Types of sacrificial aluminum anodes widely used in offshore structures

Important types of sacrificial aluminum anodes designed for offshore applications include bracelet anode, stand-off anode, and welding anode.

Core anodes are connected to the bases by means of welds or bolts before installing the structure in the sea. These anodes are generally installed on offshore jackets.

Aluminum bracelet anodes are specially designed for cathodic protection of oil and gas pipelines. These anodes are produced from alloys with high purity and very low percentage of iron and are designed with diameters appropriate to the desired pipe diameter. These anodes usually consist of two parts that are connected to each other by an internal iron belt.

- Published in Articles, Educational, Scientific