Applications of sacrificial anode systems

The method of sacrificial anodes and its applications

In the sacrificial anode method, the current required to combat the corrosion of the structure is provided by another metal, which is usually made of zinc, aluminum and magnesium. Because these sacrificial anodes do not have the ability to provide high current, sacrificial anodes are used where low current is required to protect against corrosion.

Applications of sacrificial anodes include the following:

- Where the protected structure is small.

- Items that do not have access to electricity, such as offshore platforms or pipelines.

- Items where the use of electricity is dangerous, such as inside oil storage tanks.

- Where soil specificity is low. The use of sacrificial anodes in high-strength soils is not recommended due to reduced output current.

- To fix the wandering currents.

According to the above, you can get the necessary information about cathodic protection from the sales and development unit of Tavanazob Sana’ati Kavir Company regarding the applications of the sacrificial anode system, and follow other questions about the applications of the sacrificial anode system from the sales support department.

In this regard, you can receive the contact numbers of the sales and development unit from the relevant department or send questions related to cathodic protection or sacrificial anodes via e-mail.

- Published in Articles, Educational, Scientific

Protection of water heater against corrosion

Maintenance of water heaters using a sacrificial anode

The use of water heaters in industry as well as in homes in various dimensions and shapes is essential. Therefore, its maintenance is very important. The water heater may run loudly over time as sediment builds up inside. This deposit may be due to natural minerals in the water or substances that result from corrosion of the sacrificial anode or the tank itself.

In a water heater, the sacrificial anode is visible as a rod that slowly erodes over time. The sacrificial anode is made of magnesium, aluminum or a combination of zinc and aluminum. The water in the tank causes corrosion of the inner steel of the tank by creating an electrolytic reaction. To protect the steel, a magnesium or aluminum rod anode is placed in place. After the anode corrodes, the tank steel begins to corrode and the tank fails.

Replacement time of sacrificial tank anodes

To protect the tank steel against corrosion, the sacrificial anode of the tank should be replaced every 3 to 5 years, depending on the type of tank. The warranty period of the tank can be used to determine the time of replacement of the anodes. If the anodes are not replaced in time, the tank will continue to work, but over time, the tank steel will corrode and tank replacement will be inevitable, which will cause a lot of damage.

water heater tank corrosion

How to place the sacrificial anode in the tank

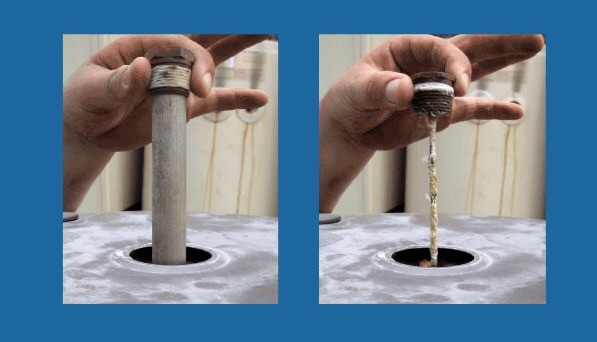

The sacrificial anodes are usually screwed to the top of the tank for easier access. Note that sometimes the length of these bars is long and you have to have enough space to take them out. Therefore, sometimes it is necessary to remove the tank to replace the sacrificial anode.

Water heater anode

What type of sacrificial anode is used in the tank?

The sacrificial anode type is usually recommended by the manufacturer. Aluminum sacrificial anode, although it may cost less, has a higher corrosion rate than magnesium anode. Also, in addition to making noise, the aluminum poured into the tank pollutes the water in the tank. Therefore, be careful never to use hot water from the tank for drinking or cooking. The most common sacrificial anode in water heater tanks is the magnesium sacrificial anode.

- Published in Articles, Educational, Scientific

Cathodic protection of underground storage tanks

Corrosion of underground storage tanks

Underground storage tanks are generally in contact with materials such as soil and sand. The electrochemical reaction between the tank and the surrounding soil (electrolyte) leads to tank corrosion. The small voltage difference on the steel surface causes a current to flow from one part of the tank to another. Corrosion occurs where current flows into the soil (electrolyte). This part in the galvanic cell is called the anode. Where the flow from the soil enters the reservoir is the cathode and corrosion does not occur.

Prevention of tank corrosion (cathodic protection of underground storage tanks)

An outer cover as well as a cathodic protection system are used to protect the underground tanks from corrosion. A suitable outer cover can protect more than 99% of the tank surface. But since there is no complete cover, in addition to the outer cover, a cathodic protection system must be used to protect the tank from corrosion. The cathodic protection system converts the tank into a cathode by applying an external current and protects it from corrosion. In cases where the amount of current required to protect the structure is small, sacrificial anodes are used. For large structures such as large diameter pipelines, an impressed current system is used.

Magnesium sacrificial anode for cathodic protection of underground storage tanks

Magnesium sacrificial anode is the most common sacrificial anode used in cathodic protection of underground tanks. Magnesium anode can protect underground tanks in any soil. To reduce the electrical resistance of the anode to soil, a magnesium anode is usually used inside a linen bag with backfill material that is a combination of gypsum plaster, bentonite and sodium sulfate. Magnesium anode is produced in two types of standard and high potential. High potential magnesium anode is used in soils with a resistance of about 10,000 ohm-cm. Based on the dimensions of the tank and the soil resistance in which the tank is located, the number and dimensions of the required anodes are determined. The two most common sizes of magnesium anodes to protect underground reservoirs are 17-pound and 32-pound anodes. The anodes are installed at a suitable distance and depth from the tank. The anode wire is connected to the top of the tank with a low-resistance electrical connection. All connections are covered with waterproofing.

In terms of cathodic protection of underground storage tanks, the technical and engineering department of Tavanazob Sana’ati Kavir Company is ready to provide consulting services for which you can contact us.

- Published in Articles, Educational, Scientific