Mixed metal oxide anode (MMO) and its applications

What is a mixed metal oxide anode?

Mixed metal oxide anodes are made of a titanium substrate coated with mixed metal oxides. The coating is applied by several thermal processes on the titanium base to create a chemical resistant layer. Due to the inherent stability of titanium, this coating achieves the best performance of the anode by strengthening the conductivity of the anode.

MMO anodes have advantages such as very low consumption rate and high current capacity. Low anode consumption rate causes the anode dimensions to remain almost constant over the life of the anode. Therefore, these anodes are widely used in impressed current systems for land and marine structures.

MMO anode applications

MMO anode is used in cathodic protection system in different types of tubes, ribbons, meshes, wires and plates. These anodes can be used effectively in all environments such as soil, fresh water and saline water. Depending on the environment in which the anode is located, two types of coatings are considered for the anode. Iridium-tantalum coating is used in soil and fresh water and iridium-tantalium-ruthenium coating is used in saline water. The anode current capacity in soil, coke or fresh water is 100Amps \ m2 and in saline water is 600Amps \ m2.

various type of MMO anodes

Types of MMO anodes

- Tubular Anode

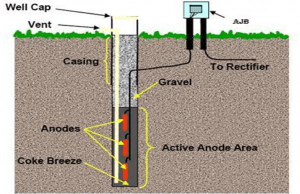

Tubular anode is the most common type of MMO anode used in cathodic protection systems. The titanium of this anode is manufactured according to ASTM B338 Grade1 standard. Tubular anodes are usually used as strings in deep wells.

cathodic protection of deep wells by tubular mmo anodes

- Ribbon Anode

The titanium base of these anodes is manufactured according to ASTM B265 Grade1 standard and uses iridium / tantalum mixed metal oxide coating. This type of anode is used to protect the external bases of aboveground storage tanks. Ribbon anodes are suitable for connection to titanium conductors by spot welding to create a network under the tank that also provides a uniform distribution of current.

- Mesh Anode

Mesh MMO anodes are used in cathodic protection systems of reinforced concrete structures. Titanium mesh anode base like ribbon anode is produced according to ASTM B265 Grade1 standard and the anode quality is checked according to NACE TM0294 standard.

- Wire Anode

Titanium wire anode is an ideal cathodic protection product for protecting the bottom of tanks, submarines and pipelines. This type of anode is made of high grade titanium with a mixed metal oxide coating and has a lifetime of more than 50 years.

- Plate Anode

These types of anodes are designed as rectangular or circular plates for use on ships and vessels.

- Published in Articles, Educational, Scientific