Types of sacrificial anode system backfills and its applications

Types of backfill and its applications:

In cathodic protection systems of pipelines or underground structures buried in the soil, the anode used is not in direct contact with the soil. This is because the minerals and chemicals in the soil may interfere with the conductivity of the stream by creating a high-strength layer. To increase the efficiency of the anode, sometimes magnesium and zinc sacrificial anodes are provided in linen bags with a backfill. The backfill material quickly absorbs soil moisture and reduces electrolyte resistance, thus improving the practical implementation of protection. Backfill materials generally include gypsum plaster, bentonite and sodium sulfate. Depending on the environment in which the anode is placed, one of the types of backfill, which is considered in the table below, is used.

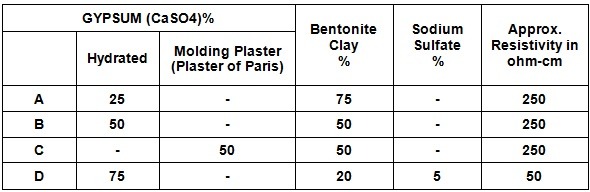

Table of combinations of different types of backfills according to IPS-M-TP-750 standard:

Due to its moisture retention properties, bentonite type A is used in areas where soil moisture is low.

Type B backfill is commonly used for sacrificial zinc anodes.

Type C backfill is useful for magnesium or zinc sacrificial anode in very wet or swampy soils to prevent the backfill from leaving the anode surface quickly.

Type D backfill, this type of backfill has low resistance and is used in areas where soil resistance is high to reduce the resistance of the anode to ground.

Dimensions of backfill bag

According to IPS-M-TP-750 standard, the diameter of the backfill bag must be at least 50 mm larger than the diameter of the anode. The backfill material should be tightly packed in the bag to prevent the anode from moving and to get enough coverage around the anode.

- Published in Articles, Educational, Scientific